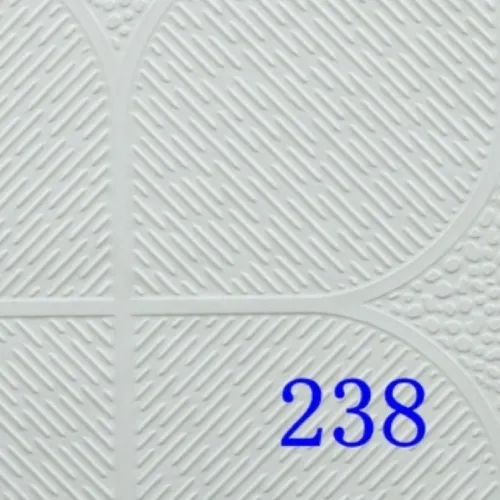

toilet grid ceiling

-

...

One of the most significant benefits of mineral fiber ceiling panels is their sound absorption capabilities. Many public spaces, such as restaurants, schools, and offices, often struggle with noise pollution and echoing. Mineral fiber panels are specifically engineered to absorb sound, making them an effective solution for controlling noise levels. Their porous structure allows them to trap sound waves, which reduces reverberation and creates a more comfortable environment for occupants. This acoustic control is particularly crucial in areas such as classrooms where concentration is key, or in offices that require a degree of silence for productivity.

...

Links

-

70: The seal suits the housing bore diameter of ϕ70 mm. -

• Low-friction torque design

- In conclusion, oil seals play a critical role in maintaining the performance and longevity of machinery. By preventing the leakage of oil and contaminants, these seals help to ensure that machines operate efficiently and reliably over extended periods of time. With their high-quality materials and precise design, oil seals are a must-have component for any mechanical system that requires reliable sealing solutions.

- Despite its unassuming presence, the double lip oil seal remains one of the unsung heroes of modern machinery. Its ability to adapt and protect under diverse circumstances is a reflection of both human ingenuity and the relentless pursuit of mechanical perfection. As technology advances and machinery becomes more complex, the double lip oil seal continues to evolve, silently ensuring that the heartbeat of industry throbs steadily and efficiently.

- In operation, oil seal rubber ensures that machinery runs smoothly by maintaining the integrity of the lubrication system. By preventing oil leaks, it not only safeguards the environment but also extends the lifespan of equipment by reducing the need for frequent maintenance and replacement. Furthermore, it shields sensitive components from contamination, thereby improving overall system performance.

Even though it’s better than other materials in terms of toughness and wear time, it is preferably used in dry-running applications. The salient demerit of this material is its cost.